Printing & Printing Finish Options Available For You

Shanghai Custom Packaging Co., Ltd offers a variety of printing and finishing services for different types of packaging materials such as paper boxes, paper bags, corrugated boxes, rigid cardboard gift boxes, and printing materials.

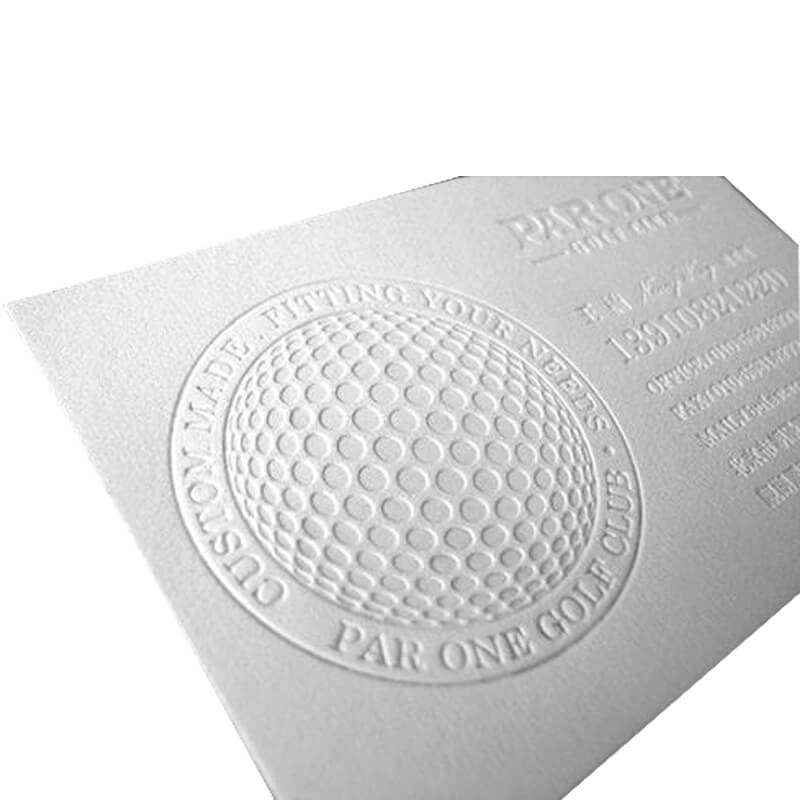

For rigid cardboard gift boxes, we use offset printing on CCNB (Clay News Back Paper) or art paper, and apply glossy varnish or matte varnish, glossy lamination or matte lamination, embossing or debossing, soft-touch film lamination, or hot foil stamping, AQ coating or spot UV varnishing.

For Kraft corrugated fiberboard, we offer flexo printing along with varnishing or lamination. We understand the importance of printing and finishing for packaging, as it creates the first impression on your customers. Let’s work together to create the perfect packaging solution for your brand.

The Benefits of Adding Printing To A Blank Packaging

Adding custom printing to cardboard packaging boxes offers several benefits for businesses. Here are a few reasons why you may want to consider custom printing on your boxes:

- Branding: Custom printing allows you to include your company logo, colors, and other branding elements on your packaging. This can help increase brand recognition and create a more professional look for your products.

- Marketing: Custom printing can also be used as a marketing tool. You can include product information, promotional messages, and other marketing materials on your packaging to help promote your products and increase sales.

- Differentiation: Custom printing can help differentiate your products from competitors. By creating unique and eye-catching packaging, you can stand out in the market and attract more customers.

- Professionalism: Custom printing on your packaging can give your business a more professional look. This can help build trust with your customers and create a positive impression of your brand.

Overall, adding custom printing to your cardboard packaging boxes can be a great investment for your business. It can help increase brand recognition, promote your products, differentiate your brand, and create a more professional look for your business.

Our Advanced Press

As a professional and reliable paper packaging manufacturer in China, we are able to provide printing services for both the inside and outside of paper boxes and bags. Our offset printing quality is ensured by using Heidelberg 4-color and 6-color machines, while our Chinese high-speed printing machine guarantees high-quality flexo printing. Before mass printing, we always check the quality and create a real sample for final approval. Our cardboard is FSC Certified.

Printing finish is equally important, and we carefully compare the artwork with the actual product under both sunlight and light machines to ensure every detail is perfect.

Our commitment is to check each paper packaging print and finish it at least three times before sending it to our customers.

Litho Offset Printing

Litho offset printing is the most popular print option for packaging boxes, especially on white CCNB coated corrugated fiberboard, rigid cardboard gift boxes, or paper bags. This printing method creates a vivid and lifelike image, ensuring that your packaging grabs the attention of consumers.

Flexo Printing

Flexo printing is a cost-effective way to print paper boxes. Using water-based ink, is an environmentally friendly option, but the colors may not be as vivid as with offset printing. This printing method is widely used on Kraft paper or corrugated board and does not require additional finishes.

Glossy Varnishing

Glossy varnished paper. Similar to glossy lamination, it is to paste up water-based oil onto the printing work. The function is to protect the printing work away from sunshine, also makes it shiny from the light or sunshine. If you need it water resistance, you may need to consider waterproof oil varnish.

Matt Varnishing

Matt varnished paper. Contrary to glossy varnishing, the matt varnishing makes the printing work seem matt, add a luxury feeling onto, and make it away from faded in a long time. Matt finish is a little expensive than glossy finish generally, but it really deserved, we strongly recommend it!

Hot Foil Stamping

Gold foil stamped business card. Hot foil stamping includes gold foil stamping, silver foil stamping, or metallic color foil stamping. Always be applied to the logo brand, texts, and graphics. The stamped area, a little embossed, has a clear touch feeling. We also supply painted edge business cards.

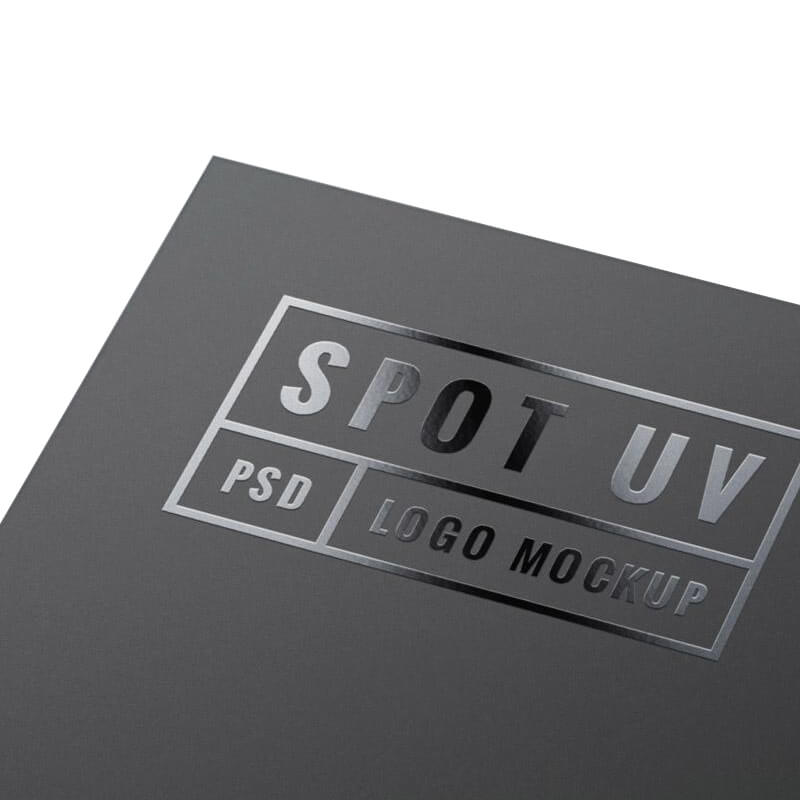

UV Varnishing

UV varnishing on paper. UV varnishing also called AQ coating, is a water-based oil onto the printing surface. Including spot UV varnishing, full over varnishing. The varnished area seems glossy and transparent, and a real touch feeling, always be applied to paper boxes, corrugated boxes, and paper bags.

Details About Wax Coating

The wax coating is a process in which a thin layer of wax is applied to cardboard packaging. This is done to make the packaging more resistant to moisture, water, and other liquids.

There are two main types of wax coating used on cardboard packaging: inline and offline. Inline wax coating is done during the manufacturing process, where a thin layer of wax is applied to the surface of the cardboard as it is being produced. Offline wax coating is done after the cardboard is produced, where a pre-coated sheet of wax is laminated onto the surface of the cardboard.

Wax coating is commonly used in the food industry, especially for packaging products that are exposed to moisture or liquids, such as fruits, vegetables, and meat products. It helps to prevent the packaging from becoming soggy or falling apart due to exposure to water or moisture.

However, it’s worth noting that wax coating can also make recycling the cardboard packaging more difficult. When the wax-coated cardboard is recycled, the wax layer needs to be removed, which can be a time-consuming and costly process.

Another method of waxing cardboard is through a process called “wax soaking“. In this method, the cardboard is immersed in a vat of melted wax, allowing the wax to penetrate the cardboard fibers.

Wax soaking is typically used for applications that require more durable and long-lasting packaging, such as heavy-duty shipping boxes, industrial packaging, and outdoor signage. The wax coating provides additional protection against moisture and rough handling, making the packaging more resistant to damage during transit or storage.

However, like inline and offline wax coating, wax soaking can also make recycling the cardboard more difficult. The wax layer must be removed before the cardboard can be recycled, which can require specialized equipment and processes.