Keep A Peaceful Mind Working With Us

Get Your Custom Corrugated Packaging Boxes Started

Find Videos of Custom Corrugated Packaging Boxes

To let You have a better understanding of our works & ability in custom corrugated packaging boxes, our marketing team has prepared some featured videos of custom corrugated packaging boxes & cartons. From the below videos, You will see printing, printing finish, box material, and detailed information. If You like, give a “like” or comment.

Custom Corrugated Boxes: A Guide to Personalized Packaging

When it comes to packaging, corrugated cardboard boxes are among the most popular choices due to their durability, versatility, and cost-effectiveness. But did you know that you can take it up a notch by customizing your corrugated boxes? In this article, we’ll dive into the world of custom corrugated boxes, from what they are to how you can order them.

- What is corrugated cardboard? Corrugated cardboard, also known as corrugated fiberboard or simply cardboard, is a type of paper board material that is composed of three layers(mainly): an inner layer called the fluting, which is sandwiched between two outer layers called the liners. The fluting provides strength and rigidity to the cardboard, while the liners protect the contents and provide a smooth surface for printing. BPS also offering five layers and seven layers of corrugated cardboard to make boxes.

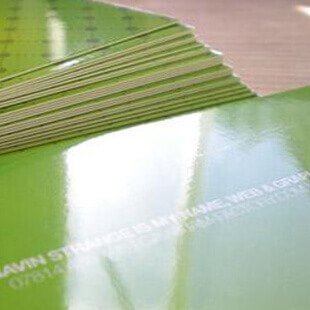

- What are custom corrugated cardboard boxes? Custom corrugated cardboard boxes are corrugated boxes that are tailored to fit specific requirements or preferences. You can customize various aspects of the box, such as the size, color, shape, print design, and even the type of fluting used. This level of customization allows you to create packaging that not only protects your product but also enhances its branding and aesthetics.

To customize your corrugated box, you can work with a packaging supplier or manufacturer that offers customization services. They will work with you to understand your needs and provide recommendations on the best options for your product. Some of the customization options available include:

- Custom box size: You can specify the length, width, and height of the box to fit your product perfectly, which minimizes the risk of damage during transport.

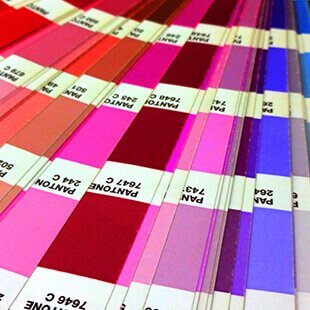

- Custom box color: You can choose the color of the box to match your brand’s colors or create a distinctive look that stands out on the shelf.

- Custom box dividers: If you need to pack multiple items in the same box, you can add dividers to keep them separated and prevent damage.

- Custom box shapes: You can create unique box shapes that add an element of surprise to your packaging and make your product more memorable.

- Different corrugated box styles/types. There are several types of corrugated boxes, each designed for specific purposes. Here are some of the most common styles/types:

- Regular Slotted Container (RSC): This is the most common type of corrugated box, characterized by four flaps that meet at the center of the box.

- Full Overlap Container (FOL): This type of box has flaps that completely overlap, providing extra strength and protection for heavy items.

- Half-Slotted Container (HSC): HSC boxes have only one set of flaps, making them ideal for products that need to be slid in and out of the box easily.

- Telescoping Boxes: Telescoping boxes consist of two pieces – a lid and a base – that fit together to create a box that can be adjusted to fit different product sizes.

- Mailer Boxes: Mailer boxes are self-locking boxes that are ideal for shipping small or flat items.

- Point of Sale (POS) Displays: POS displays are corrugated boxes that are designed to be used as retail displays, such as counter displays or floor displays.

- How to order custom corrugated boxes. Ordering custom corrugated boxes is similar to ordering regular corrugated boxes. Here are the basic steps:

- Contact a packaging supplier or manufacturer that offers customization services. (For example, contact us)

- Provide the specifications for your box, including size, color, print design, and any other customization options you want.

- Request a quote and review it to ensure it fits within your budget.

- If the quote is acceptable, request a prototype sample to test.

- Full run of the order if the sample is approved, and spread the changes needed.

Make Your Custom Corrugated Packaging Boxes Unique with SCP

With BPS, you need to inform us about your request, and we will do the rest for you.

To make sure satisfactory results, we control the quality from the below points:

- Compare printing file to sample, sign the sample from customer’s confirmation, and archive the sample in storge.

- Compare the first piece of a bulk order to the sample, sign the example, and keep in a file.

- Before shipping, take 3% percent of the order to recheck quality. If passed, then go to load into the container.

- Quality 100% satisfactory guarantee.

- Strict production management to ISO9001.

We pack your products with love. With years of experience, we genuinely believe that packing is the final necessary process for a beautiful order. We carefully pack each item in the order, using different strength packing methods to ensure that all boxes arrive in good condition. So, as we said, please give us a chance to perform!

We are flexible with our packing methods, and depending on the thickness of the cardboard, we may use different packing techniques. If you have any special requests or concerns about packing, please send us a message, and we will suggest and proceed accordingly.

How To Calculate A Custom Cardboard Corrugated Box Price?

When it comes to packaging, cardboard boxes are a popular choice for businesses of all sizes. They are affordable, eco-friendly, and can be customized to fit almost any product. However, if you are ordering cardboard packaging boxes for your business, it is important to understand how the price is calculated so that you can make an informed decision. Here is a step-by-step guide to help you calculate the price of a cardboard packaging box.

Step 1: Determine the Box Size

The first step in calculating the price of a cardboard packaging box is to determine the size of the box. Measure the length, width, and height of the product that will be packed in the box, and add an additional 2-3 inches to each dimension to allow for cushioning and protection. This will give you the external dimensions of the box.

Step 2: Choose the Type of Cardboard

Cardboard boxes come in a range of materials, including single-wall, double-wall, and triple-wall cardboard. Single-wall cardboard is the most affordable option, while triple-wall cardboard is the strongest and most expensive. Choose the type of cardboard that best suits your needs and budget.

Step 3: Determine the Quantity

The next step is to determine the quantity of boxes that you will need. Most cardboard box manufacturers offer bulk discounts for larger orders, so it is important to determine how many boxes you will need upfront to take advantage of any cost savings.

Step 4: Calculate the Board Feet

The price of a cardboard box is calculated based on the board feet, which is the amount of cardboard used to create the box. To calculate the board feet, multiply the length, width, and height of the box to get the cubic inches, and then divide by 1,728 (the number of cubic inches in a cubic foot). This will give you the board feet.

Step 5: Calculate the Price

Once you have determined the board feet, you can calculate the price of the cardboard packaging box. Multiply the board feet by the cost per board foot (which can be obtained from the cardboard box manufacturer), and then multiply by the quantity of boxes needed. This will give you the total cost of the cardboard packaging boxes.

Additional Factors to Consider

In addition to the steps above, there are other factors that can affect the price of a cardboard packaging box. These include:

- Printing: If you require custom printing on the box, this will add an additional cost.

- Inserts: If you require inserts such as dividers or foam padding, this will also add to the cost.

- Delivery: The cost of shipping or delivery will vary depending on the location and quantity of boxes ordered.

In conclusion, calculating the price of a cardboard packaging box requires careful consideration of factors such as size, quantity, type of cardboard, and additional features such as printing and inserts. By taking the time to understand the pricing process, businesses can make informed decisions and choose the most cost-effective packaging solution for their products.

You May Also Interested In

You Are Invited To Be One in The List

I’m thrilled working with Shanghai BPS, and they just gave what I need. I would come back to repurchase it. (U.S customers try their Delivery to door service, five stars strongly recommend!)

Sourcing on Google with days then found them, and I have been to their factory. Skilled workers, flexible payment terms, and Fast delivery time, worthy to come back to buy again!

BPS was introduced by a friend working in GIPHY, and I like the corrugated cartons, they fill bottles and send back to my factories in Shenzhen. Thanks, you have got my long-time business.