Description of PET / PVC Window on Box

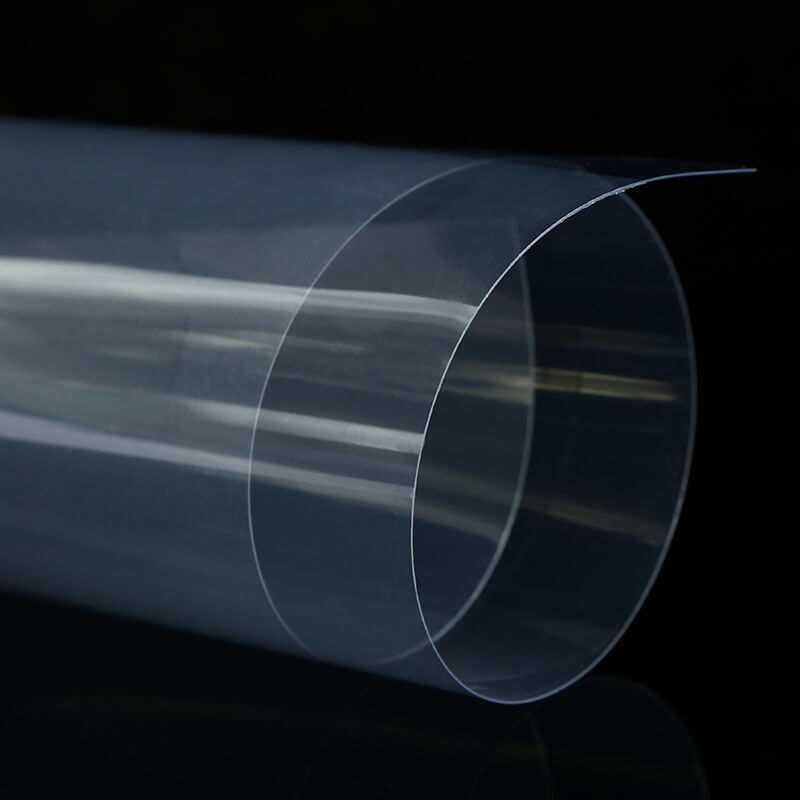

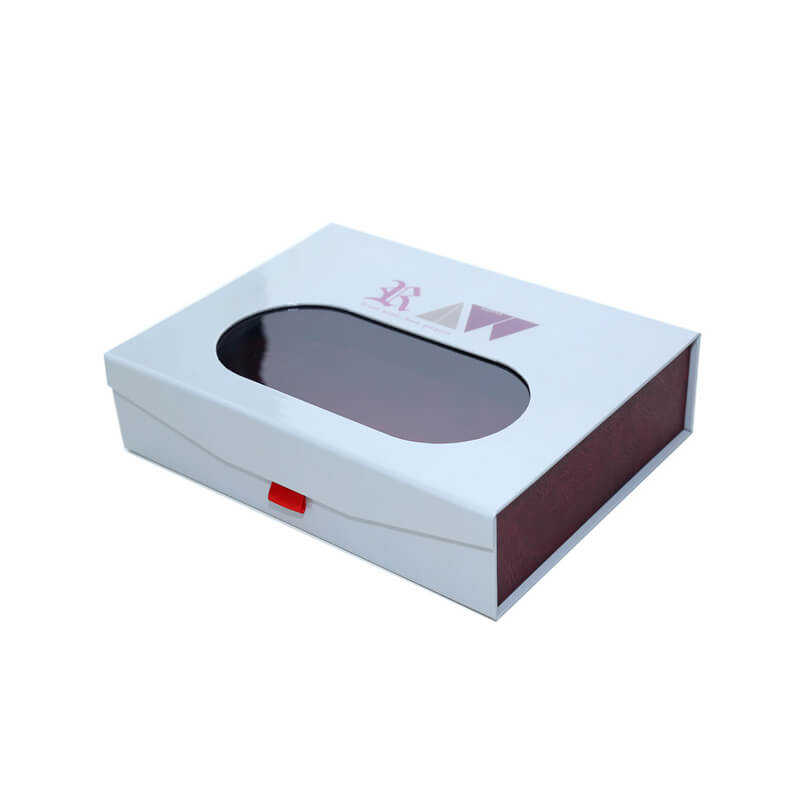

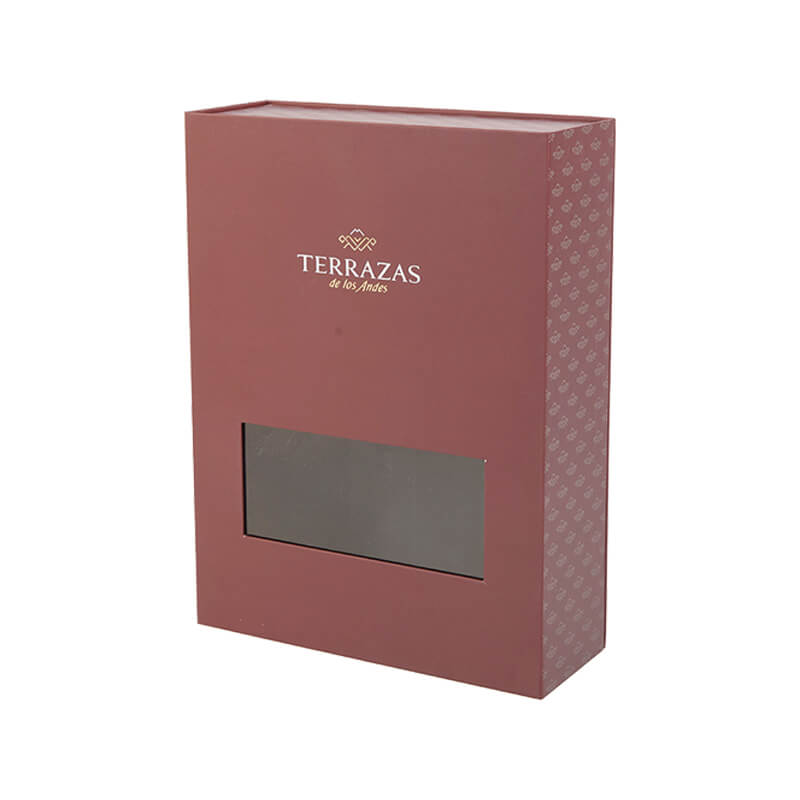

The plastic window plays an essential role in the paper packaging industry as it allows customers to see the products inside and adds additional features to the packaging. At Box Packing Solution, we offer PVC and PET window options for your box packaging. The plastic window can be positioned in the middle, on the side, or at the end of the box, on one side or across the box body. The thickness ranges from 0.1 millimeters to 20 millimeters.

The plastic window patching process is fast, and we always use transparent glue to ensure a nice appearance of the final box.

Benefit of Adding The PET/PVC window

One of the key advantages of using a PVC/PET window on cardboard packaging is that it allows customers to see the contents of the package without having to open it. This can be particularly useful for products that need to be displayed or for gift packaging where the contents need to be visible. By providing a clear view of the contents, the packaging can help to attract potential customers and increase sales.

In addition to the marketing benefits, a PVC/PET window can also provide practical advantages. For example, it can help to protect delicate or fragile items from damage during shipping or transport. By allowing customers to inspect the contents of the package before opening it, they can also avoid any potential disappointment or dissatisfaction if the product does not meet their expectations.

Another advantage of using a PVC/PET window is that it can help to reduce packaging waste. If customers can see the contents of the package before opening it, they are less likely to return it due to a misunderstanding or dissatisfaction with the product. This can help to reduce the amount of packaging waste generated and can also help to lower the cost of returns for businesses.

Finally, PVC/PET windows are often made from recyclable materials, making them a more environmentally friendly option than traditional plastic packaging. By choosing packaging materials that can be recycled, businesses can help to reduce their environmental impact and appeal to customers who prioritize sustainability.

PVC Window

PVC stands for Polyvinyl Chloride. When made into sheets for packaging windows, PVC has its advantages and disadvantages:

- PVC has a distinctive plastic smell, which makes it unsuitable for food packaging.

- It is cheaper compared to other plastic materials used for windows.

- PVC is easy to adhere to glue, making it a good choice for attaching to paper boxes.

- However, it may weaken and become prone to damage along folding lines after multiple folds.

Tips Before Using PVC Window

- PVC windows should not come into direct contact with food.

- The total area of the PVC window should not exceed 50% of the whole box, or the box structure may be compromised.

- Keep the PVC window clean to ensure that your packaging looks clean and attractive.

- The PVC window should never detach from the paper box.

PET Window

Different from the PVC window, PET is short for Polyethylene terephthalate and has better quality and eco-friendly performance. The features of a PET window are:

- Higher price.

- Eco-friendly, with good transparent quality and no odor.

- Lightweight and easy to clean.

- More durable than other plastic materials.

Tips to Keep in Mind Before Using PET Window:

-

If the window extends across more than one side of the box, ensure that there is a pre-fold line on the window for better folding.

-

The price of PET window is around 50% higher than that of normal PVC window.

-

PET window cannot be stuck with yellow glue as it may damage its elements.

How Much Does The PET/PVC Window Cost?

The price of adding a PET/PVC window to a cardboard box can depend on several factors, including the size and shape of the window, the thickness and quality of the PET/PVC material, and the quantity of boxes being ordered. In general, the cost of adding a PET/PVC window to a cardboard box can be calculated using the following steps:

-

Determine the size and shape of the window: The size and shape of the PET/PVC window will impact the amount of material needed and the cost of production. The size and shape should be carefully considered to ensure that it meets the needs of the product and provides an attractive display while minimizing waste.

-

Choose the thickness and quality of the PET/PVC material: The thickness and quality of the PET/PVC material used will impact the clarity and durability of the window. Higher quality materials may cost more but can provide a longer-lasting and more attractive display.

-

Calculate the cost of the PET/PVC material: Once the size and quality of the PET/PVC material have been determined, the cost of the material can be calculated based on the square footage needed for each window.

-

Estimate the cost of production: The cost of producing the PET/PVC window and integrating it into the cardboard box will depend on the complexity of the design and the quantity being produced. This cost can be estimated based on the production process and the labor and equipment needed.

-

Add up the total costs: The total cost of adding a PET/PVC window to a cardboard box can be calculated by adding the cost of the PET/PVC material and the cost of production. This total cost can then be added to the overall cost of the cardboard box to determine the final price.

Why Choose Us as Your PET / PVC Window Supplier?

At Shanghai BPS, we understand that many of our customers require open windows for their packaging needs. That’s why we offer a variety of PVC and PET windows for your box packaging needs, and we have the following advantages:

-

Quality Check: We conduct rigorous quality checks on the window position, thickness, and stick process to ensure that the final product meets your expectations.

-

Dust-free Workshop: Our 600 square meter dust-free workshop ensures that the PET / PVC windows are kept away from dust, providing a clean and clear window for your packaging.

-

Multiple Quality Checks: We conduct several quality checks throughout the production process to ensure that the final product meets our strict quality standards before leaving our factory.