What is Rigid Cardboard?

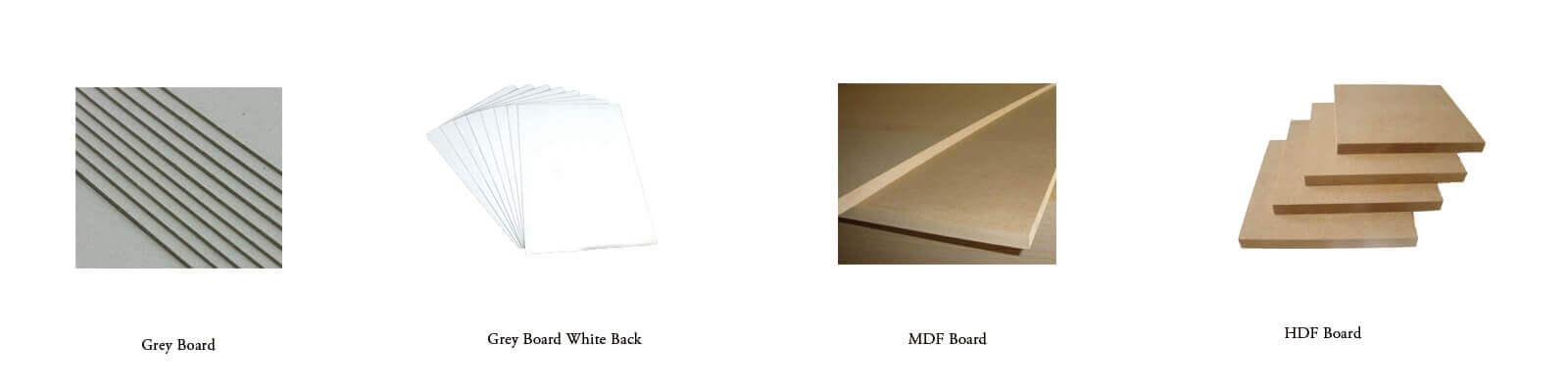

Rigid cardboard refers to a type of packaging material that is characterized by its stiffness and durability. The term “rigid cardboard” is typically used to describe three different types of board materials: chipboard, greyboard, and wood board. These materials have varying degrees of thickness, ranging from 1mm to 10mm, and are typically composed of multiple layers that are laminated together to create a single, solid sheet.

What is a Rigid Cardboard Box?

A rigid cardboard box is a type of packaging box that is made from rigid cardboard material. These boxes are typically constructed with thick walls and a sturdy base, which makes them ideal for protecting delicate or fragile items during shipping and handling. Rigid cardboard boxes come in a variety of shapes and sizes, and are often used to package high-end or luxury products due to their professional appearance and superior protective properties.

Rigid Box Styles

There are several different styles of rigid cardboard boxes, each of which offers unique benefits and features. Some of the most common rigid box styles include:

- Lift-off lid boxes: These boxes feature a separate lid that can be lifted off to access the contents of the box. This style is often used for high-end products such as jewelry, watches, and electronics.

- Collapsible boxes: These boxes are designed to be easily assembled and disassembled for storage and transportation. They are often used for retail displays or as packaging for subscription boxes.

- Drawer sliding boxes: These boxes feature a sliding drawer that can be pulled out to access the contents of the box. They are often used for luxury products such as cosmetics or perfumes.

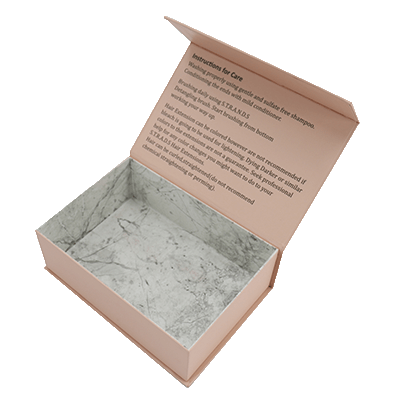

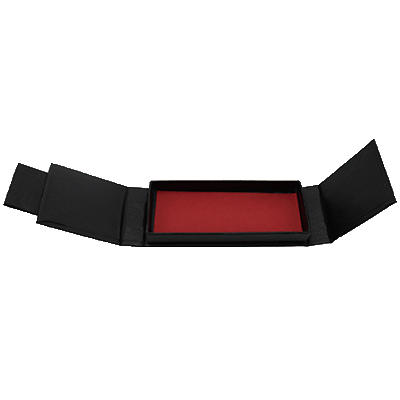

- Magnetic closure boxes: These boxes feature a magnetic closure that keeps the lid securely in place. This style is often used for high-end products such as wine, spirits, and gourmet food items.

Customization Options for Rigid Cardboard Boxes

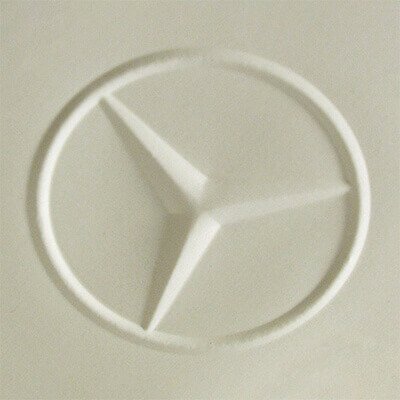

One of the main benefits of rigid cardboard boxes is that they can be easily customized to meet the specific needs of a business or product. Some of the most common customization options for rigid cardboard boxes include:

- Custom box sizes: Rigid cardboard boxes can be made in almost any size or shape, allowing businesses to create packaging that perfectly fits their product.

- Custom box colors: Rigid cardboard boxes can be printed in a variety of colors and patterns, allowing businesses to create packaging that reflects their brand and product.

- Custom box inserts: Rigid cardboard boxes can be fitted with custom inserts such as foam padding or molded plastic trays, which can help protect and showcase the product inside.

Applications of Rigid Cardboard Boxes

Rigid cardboard boxes are used to package a wide range of high-end or luxury products, including:

- Wine and spirits: Rigid cardboard boxes are often used to package high-end wines, spirits, and gourmet food items.

- Cosmetics and beauty products: Rigid cardboard boxes are commonly used to package cosmetics, perfumes, and other beauty products.

- Jewelry and watches: Rigid cardboard boxes are often used to package luxury jewelry and watches, as they provide superior protection and a professional appearance.

- Electronics: Rigid cardboard boxes are commonly used to package high-end electronics such as smartphones, laptops, and tablets.

- Food items: Rigid cardboard boxes are sometimes used to package high-end food items such as chocolates or baked goods.

In conclusion, rigid cardboard boxes are a versatile and highly customizable packaging solution that offers superior protection and a professional appearance. They can be customized in a variety of ways, from size and color to the inclusion of custom inserts.

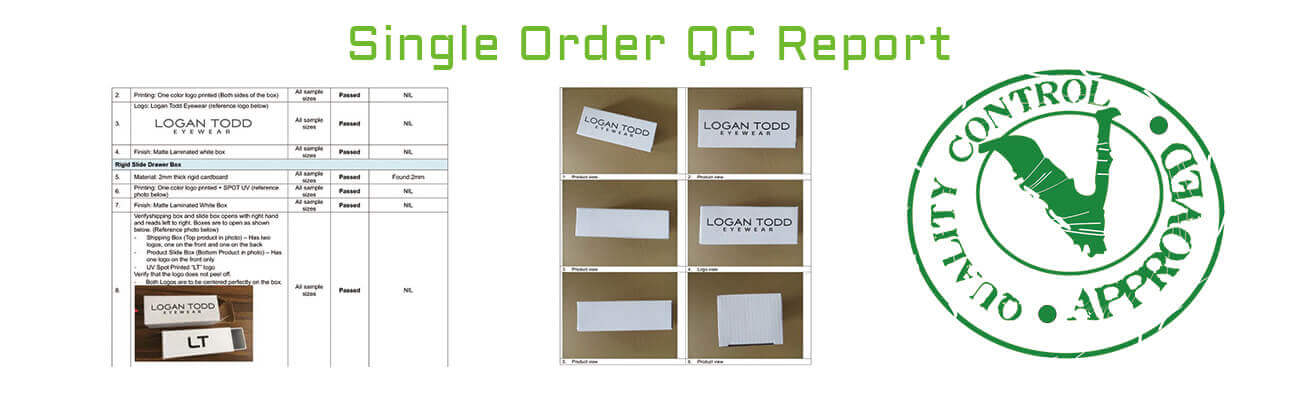

What Do We Supply With Custom Rigid Boxes

Order Process of Custom Rigid Boxes

Are you tired of using flimsy packaging that fails to protect your products during shipping? Do you want to ensure that your products reach your customers in pristine condition? Then it’s time to switch to rigid cardboard boxes.

Rigid cardboard boxes are made from a stiff and strong material that provides unparalleled protection for your products. Designed to withstand the rigors of shipping, handling, and storage, these boxes ensure that your products arrive in the same condition as they were when they left your facility.

But that’s not all. Rigid cardboard boxes are also highly customizable. With a variety of sizes, shapes, and printing options to choose from, you can create the perfect packaging solution for your products. This customization allows you to showcase your brand and increase brand recognition, which can help build brand loyalty and increase customer satisfaction.

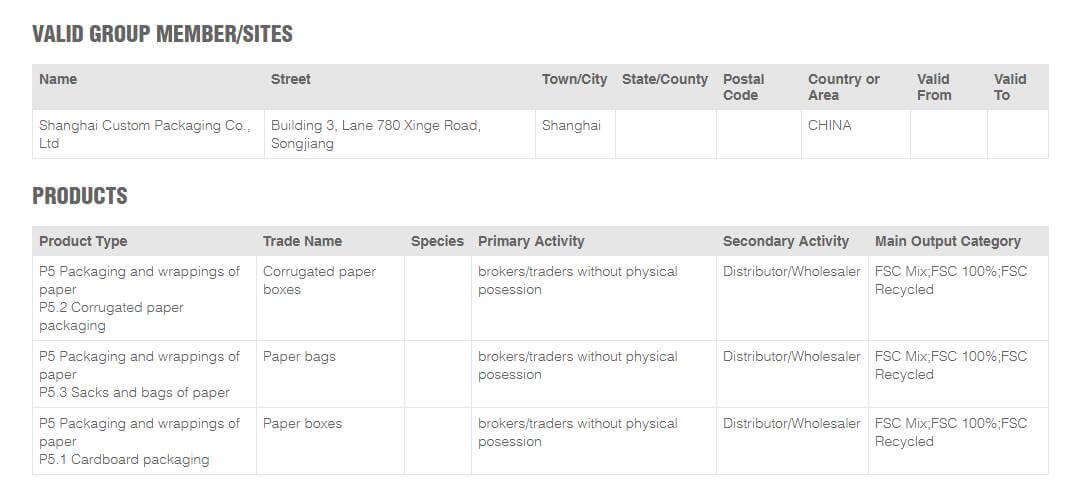

In addition to their durability and customization options, rigid cardboard boxes are also eco-friendly. Made from recycled materials, these boxes are recyclable and biodegradable, making them a great choice for businesses looking to reduce their carbon footprint.

And the best part? Rigid cardboard boxes are cost-effective. With their strength and durability, these boxes reduce the risk of damage during shipping, which can save you money on replacements and returns.

In conclusion, if you’re looking for a packaging solution that offers protection, customization, eco-friendliness, and cost-effectiveness, look no further than rigid cardboard boxes. Make the switch today and see the difference for yourself!